What we do

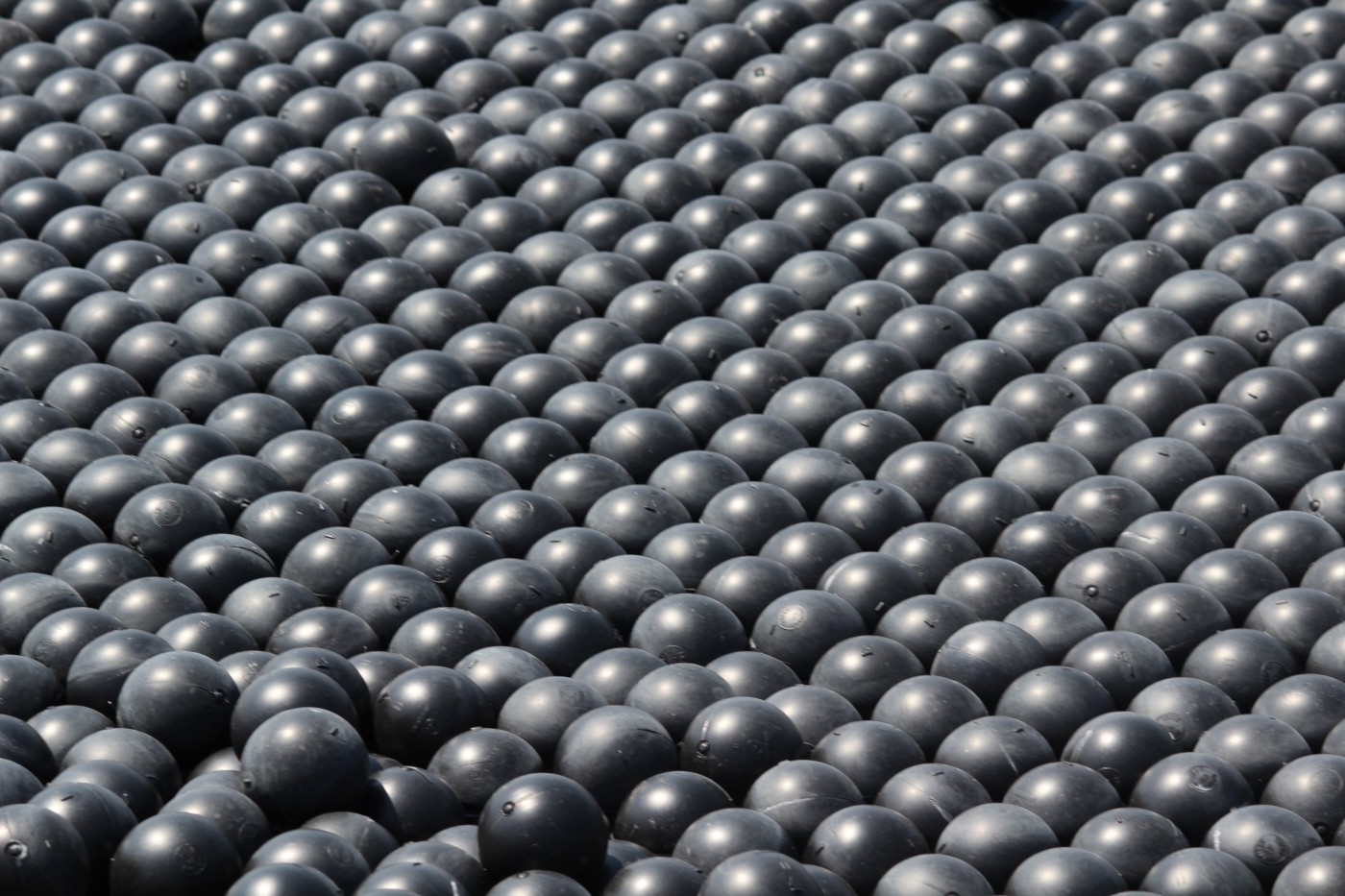

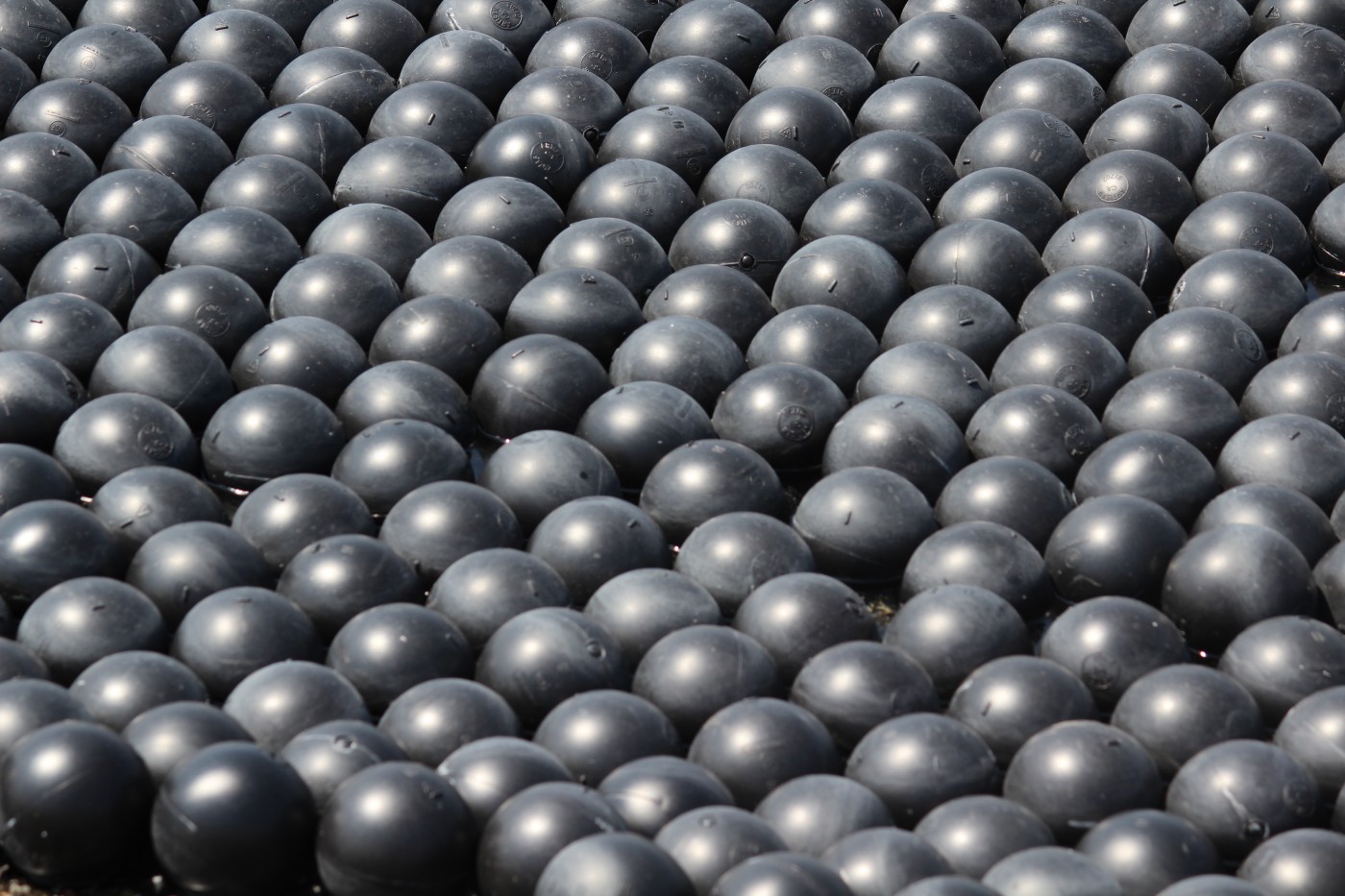

Artisan Screen Printing has been delivering quality blow molded products to companies like yours since 1994. At Artisan Screen Printing we are committed to perfection in design, materials, and production. Your success can be built on our competitive pricing and on-time delivery. Artisan Screen Printing's extensive experience in the design, engineering and manufacturing of molds, extrusion blow molded parts, and auxiliary services puts your company and products out in front.The Blow Molding Process

Blow molding is a low-pressure process in which a hot, hollow pre-form is blown into a larger, more complex hollow shape. Many thermoplastic resins and engineering resins may be used for molding of bottles, industrial and technical-parts applications. High density polyethylene, polyvinyl chloride, polyethylene terephthalate, and polypropylene are the resins most used for bottle applications. Typical industrial blow molding applications includes fuel and oil tanks, industrial drums and containers, shipping containers, labware, recreational vehicles, lawn-and-garden equipment, carrying cases,and toys. Here are the various types of blow molding and their applications:Extrusion Blow Molding

- Most widely used blow molding technique today.

- This process can be used to form thermoplastics into a wide range of hollow, thin-walled, one-piece parts.

- An extruder melts the plastic and pushes it through a die to produce a parsion or tube.

- A mold with the desired cavity shape closes around the parison, pinching shut one end and clamping the other around a blow pin. The parsion is cut from the extruder simultaneously.

- Air from the blow pin enter the parison and the parison expands or stretches into the shape of the cavity.

- Water passes through the mold and cools the plastic until it will hold its shape.

- The air pressure is then released, the mold opens, and the molded part is ejected.

- Products: bottles, gasoline tanks, toys, business machine panels.

Injection Blow Molding

- This process is commonly used for blow molding bottles.

- It can produce bottles which are as large as 5 gal in capacity. Products: mostly used for small, regularly shaped bottles and hollow industrial parts that would be difficult to mold using the extrusion-blow molding process.

Blow Molding with Engineering Resins

- It is most suitable for large parts that need stiffness and some complexity.

- Plastic replacements for sheet-metal covers and enclosures for products such as computers.

- Handles modest volumes.

- Tooling is faster and less costly than that of injection molding and structural-foam processing alternatives.

- Engineering resins used for this process include modified polyphenylene ether/polyphenylene oxide which contribute important thermal, flame, and modulus properties

- Further stiffening can be achieved by using ribbing, foam filling, tackoffs, or inserted stiffeners such as metal rods or wood.

- Products: computers and business equipment

- Product Design & Engineering [Artisan Screen Printing offers full design and mold engineering capabilities.]

- Beginning with an idea, a sketch, blueprints, or imported CAD files, Artisan Screen Printing has the requisite engineering capabilities to fully develop and manufacture your blow molding projects. Often several components of an assembly can be redesigned into a single unit.In-house engineering is supplemented by a variety of freelance artists, sculptors, and industrial designers. Models can be produced traditionally or via stereo lithography. Existing models can be digitized or duplicated. More commonly, a digital solid model representation is created on a computer and can then be easily electronically distributed.

- Mold Making [Artisan Screen Printing brings technology and experience together to create your vision in a cost effective program.]

- Competitive pricing, shorter deliveries and a greater demand for precision requires Artisan Screen Printing to be a leader in building molds. That's why we employ the latest CNC hardware and software.We can take CAD files and create simple to extremely complex molds. Precision built molds and their associated tooling are an essential ingredient to the successful production of your plastic components.CONTACT Artisan Screen Printing to discuss choosing the appropriate tooling for your project!

- Quality Engineering & Manufacturing

- Artisan Screen Printing offers extensive support before, during, and after your project has been completed

- Blow Molding [Artisan Screen Printing is equipped to handle any and all of your blow molding requirements with single, dual, and multiple cavitation BEKUM blow molding machines.]

- Continuous extrusion blow molding is the primary focus at Artisan Screen Printing, Inc. The continuous extrusion process is commonly used to produce articles from a few milliliters up to several thousand liters.Our German-built BEKUM blow molding machines are suited to run up to six cavity molds in a capacity range of 2oz (40ml) to 3gallon (11.35 liters). Our blow molding services include mold sampling and prototype production, short-runs, and high output production. Light weight containers or thick walled pressure vessels; wide mouth jars or handleware; clear, opaque, or colored; disposable or durables; medical or industrial; Artisan Screen Printing, Inc. has probably done it. Artisan Screen Printing, Inc. wants your most challenging applications.

- Auxiliary Services [Artisan Screen Printing's secondary machining, packaging, and decorating puts the finishing touches to your product and makes it ready to go to market.]

- Artisan Screen Printing, Inc. offer a variety of secondary services. After your part has been molded we can complete the manufacturing process by using our experience to put the finishing touches that will give your product that "Jump Off The Shelf Look".

- Decorating

- Labeling

- Sealing

- Filling

- Assembly

- Secondary Machining

- Packaging

- Artisan Screen Printing, Inc. offer a variety of secondary services. After your part has been molded we can complete the manufacturing process by using our experience to put the finishing touches that will give your product that "Jump Off The Shelf Look".

- On-Time Delivery

- Artisan Screen Printing's success comes from our priority driven program that gives you the confidence that your products will be completed on-time and with the quality you demand. Shipments are made in compliance with the customer's time, mode, and cost requirements.

Decorating

Decorating